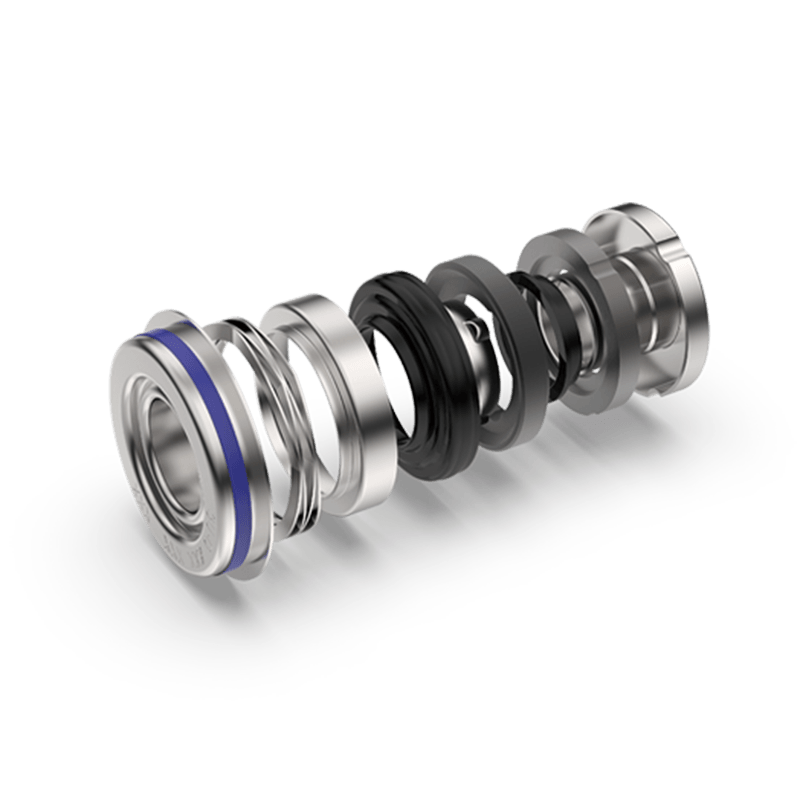

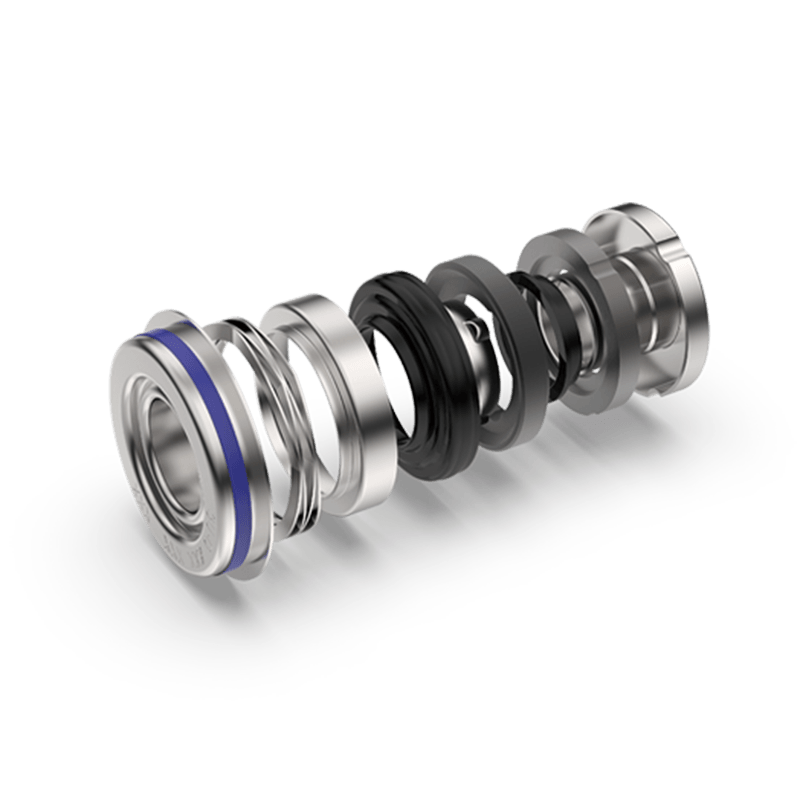

Mechanical seal, also known as end face seal, has at least one pair of end faces perpendicular to the axis of rotation. Under the action of fluid pressure and compensating mechanical external force (or magnetic force), together with the cooperation of auxiliary seals, the end face remains in contact with the other end face. slide to prevent fluid leakage. Due to the close fit of the end faces, a tiny gap is formed between the sealing end faces. When a medium passes through this gap, an extremely thin liquid film is formed, which causes resistance to prevent leakage, and lubricates the end faces to obtain a long-term sealing effect. Mechanical seals are widely used because of their good sealing performance, stable operation, less leakage, low friction power consumption, long service life, little wear on the shaft, and can meet the requirements of various working conditions. But the structure is more complex, the manufacturing precision is high, the price is more expensive, and the maintenance is inconvenient.

According to the equipment, it can be divided into pumps, kettles, centrifuges, fans, submersible pump motors, refrigerators, internal combustion engines, cooling water pumps, marine pumps and others.

Classified by principle of action:

1. Logarithm of sealing end faces: single end face, double end face, multi end face. The double end faces are further divided into axial double end faces and radial double end faces.

2. According to the unloading or non-unloading of the fluid pressure acting on the sealing end face, it can be divided into: unbalanced, partially balanced and fully balanced.

3. According to the static ring installed on the inside or outside of the sealing end face, it is divided into built-in type and external-mounted type.

4. If the spring is set in the fluid, it is a built-in spring, otherwise it is an external spring.

5. According to the number of springs of the compensation mechanism, it is divided into single spring type and multi-spring type.

6. According to whether the elastic element rotates with the shaft, it is divided into rotary and static mechanical seals.

7. If the leakage direction of the sealing fluid between the sealing end faces is consistent with the centrifugal direction of the shaft rotation, it will be an external flow, otherwise it will be an internal flow.

According to whether the sealing end face is in direct contact or not, it is divided into contact type mechanical seal, otherwise it is non-contact type, which can be divided into hydrostatic pressure type and hydrodynamic pressure type. According to whether there are bellows, it can be divided into non-bellows type bellows, which can be divided into metal bellows, PTFE bellows, rubber bellows and so on.

Classification according to the working conditions: high temperature mechanical seal, medium temperature mechanical seal, normal temperature mechanical seal and low temperature mechanical seal. -50, 80, 200, for the commonly used temperature boundary.

According to the pressure of the sealing chamber: ultra-high pressure, high pressure, low pressure, normal pressure, negative pressure and so on. 0.8, 5, 15mpa are commonly used dividing lines.

According to the speed, it can be divided into: super high speed, high speed, medium speed, low speed, etc. 2, 10, 30, 100m/s are commonly used boundaries.

According to the characteristics of the medium, there are specific special mechanical seals.

Mechanical Seals Components Supplier

Mechanical Seals Components Supplier

英语

英语 西班牙语

西班牙语